Safety

Woodworking machines are highly dangerous even in the hands of a skilled operator. In the interest of your safety it is important to wear Personal Protective Equipment (PPE) at all times when using this machine. Wearing the correct PPE can protect you from projectiles, noise, dust and many other elements.

You are advised to wear ear, eye and foot protection when using this machine.

If you want to learn more about PPE or the laws that require you to wear it, please visit one of the links below.

Personal Protective Equipment and Respiratory Protective Equipment

Publisher: Health & Safety Authority - IRL

Link: http://www.hsa.ie/eng/Topics/Personal_Protective_Equipment_-_PPE/

Personal protective equipment (PPE) at work

Publisher: Health & Safety Executive - UK

Link: http://www.hse.gov.uk/pubns/indg174.pdf

Safe Procedure

Before carrying out any setup or maintenance operations on this machine you MUST first isolate or knock off the electricity supply.

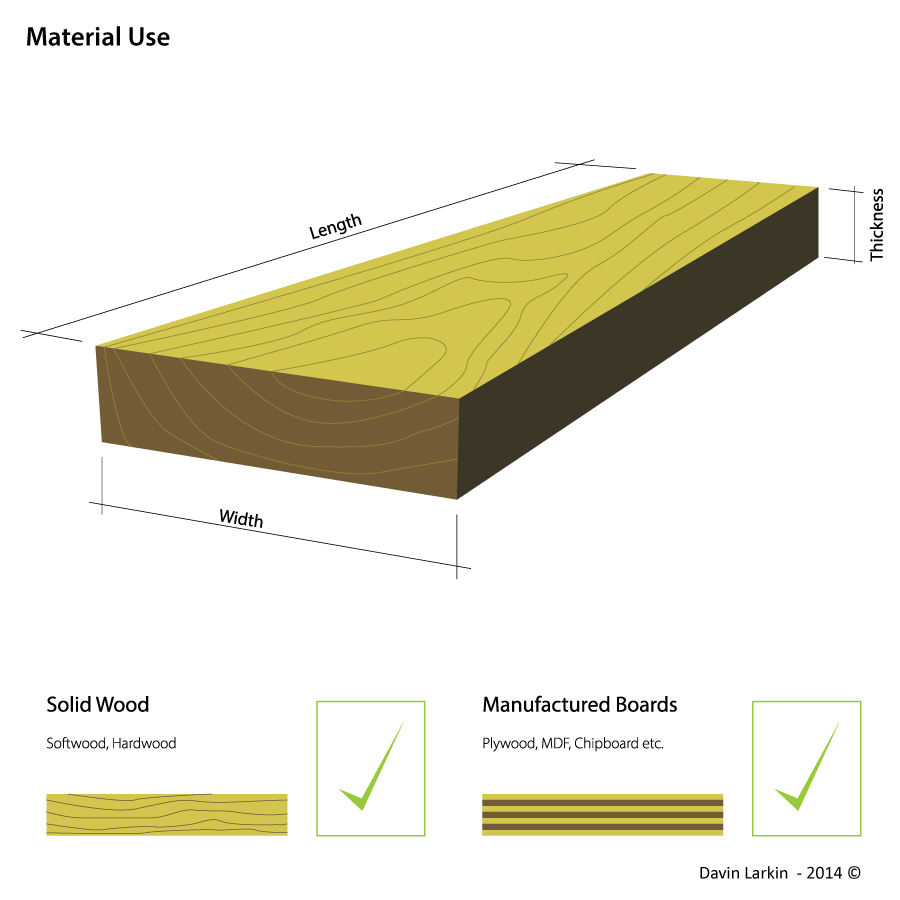

Materials

Depth

WWrasp advises a maximum safe cutting depth of 200mm when using this machine.This applies when the piece you are cutting is orientated either on its width or thickness dimension.

Width

The maximum width of material that can be cut is dependant on the size of your machine table which directly relates to the size of the machine you are using.

Materials

This machine is mainly used for cutting solid wood and manufactured boards.

Most band saws are fitted with blades that have been designed to cut wood. If you wish to cut other none wood materials such as metal, arcylic etc. it is advised that you ensure the correct blade is fitted to your machine before progressing.

Setup

Before switching on the Narrow Band Saw always:

- check the correct saw blade is fitted for the job you are about to undertake.

- ensure the saw blade is in tension

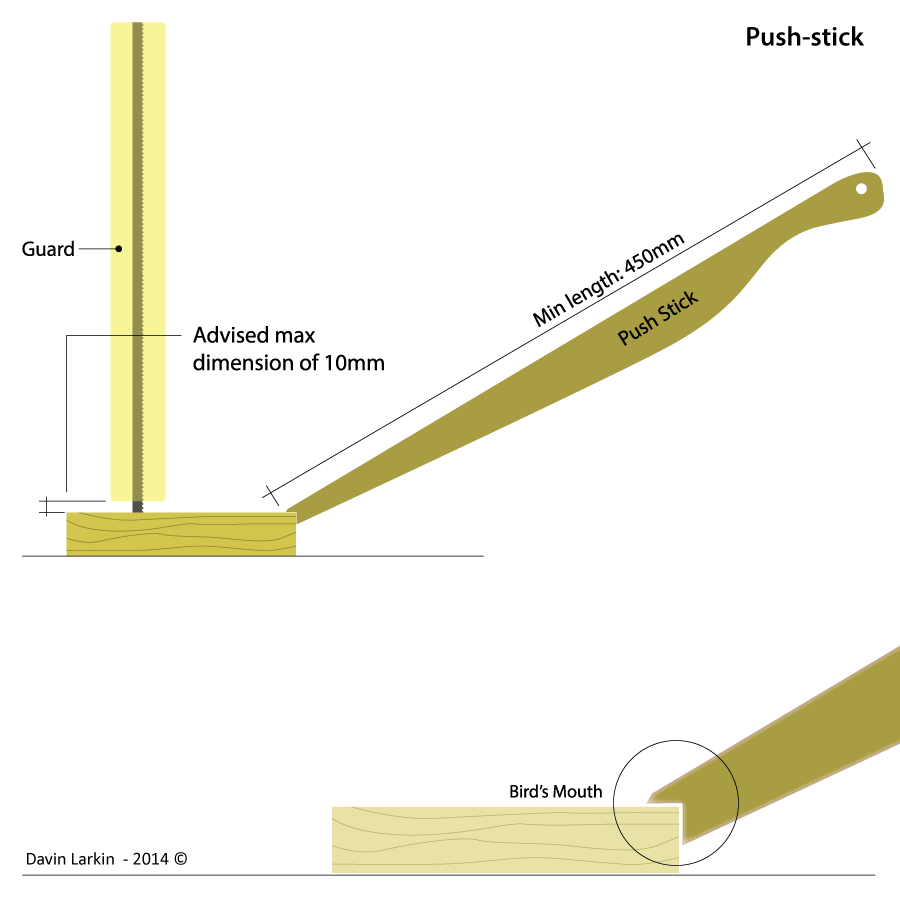

- adjust the guard as close as possible to the workpiece. WWrasp advises a maximum distance of 10mm above the workpiece where possible.

- ensure blade guides give support to the whole of the blade width up to the teeth gullets. Blade guides do not grip the blade, they should set a small fraction away

- ensure that the thrust wheel is adjusted correctly. The thrust wheel never comes into contact with a blade at rest - set 0.5mm away

Push Stick

A push-stick MUST be available to feed small components

Push-sticks should be at least 450mm long with a ‘bird’s mouth’

Operation

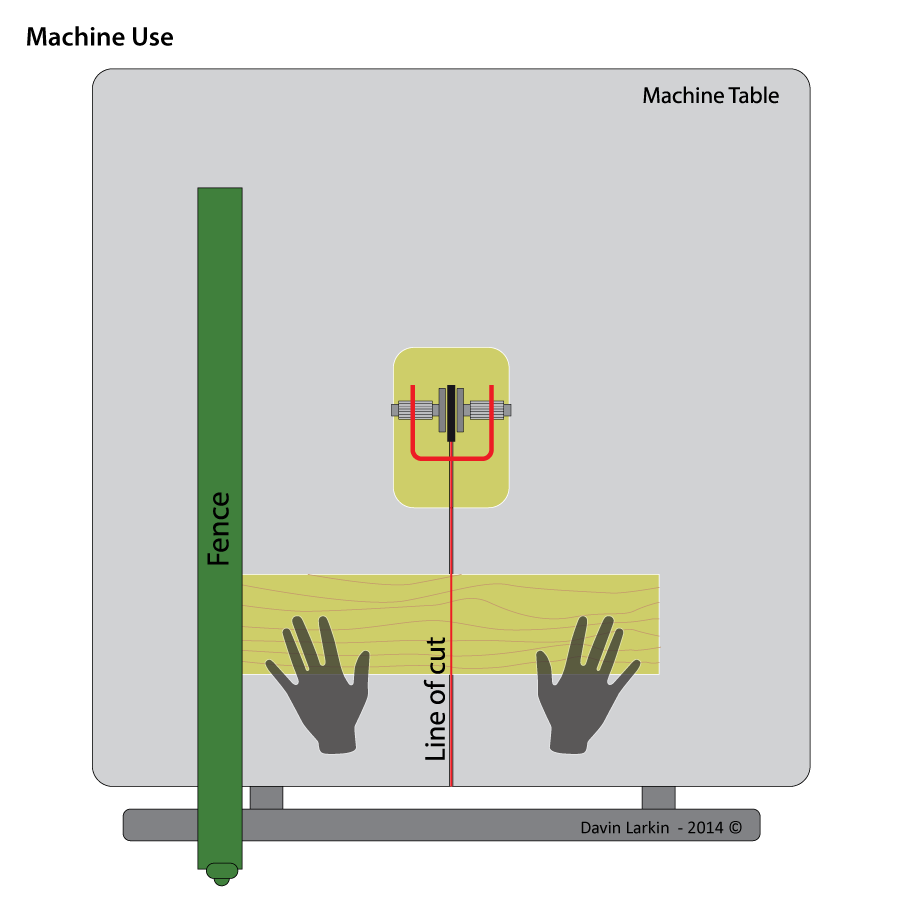

During UseFeed the stock easily – let the saw do the work.

If excess pressure is required the blade may twist or break, and there is the risk of your hands slipping into the moving blade.

NEVER PUT YOUR HANDS IN THE LINE OF CUT FOR ANY REASON WHILE THE MACHINE IS RUNNING.

If a cracked blade (indicated by a regular clicking sound) is detected the machine should be switched off immediately.

After Use

Switch OFF the machine when finished and if applicable apply the brake after use, or when leaving the machine temporarily.Someone else may want to use the machine and not notice that the saw blade is running

Regulations

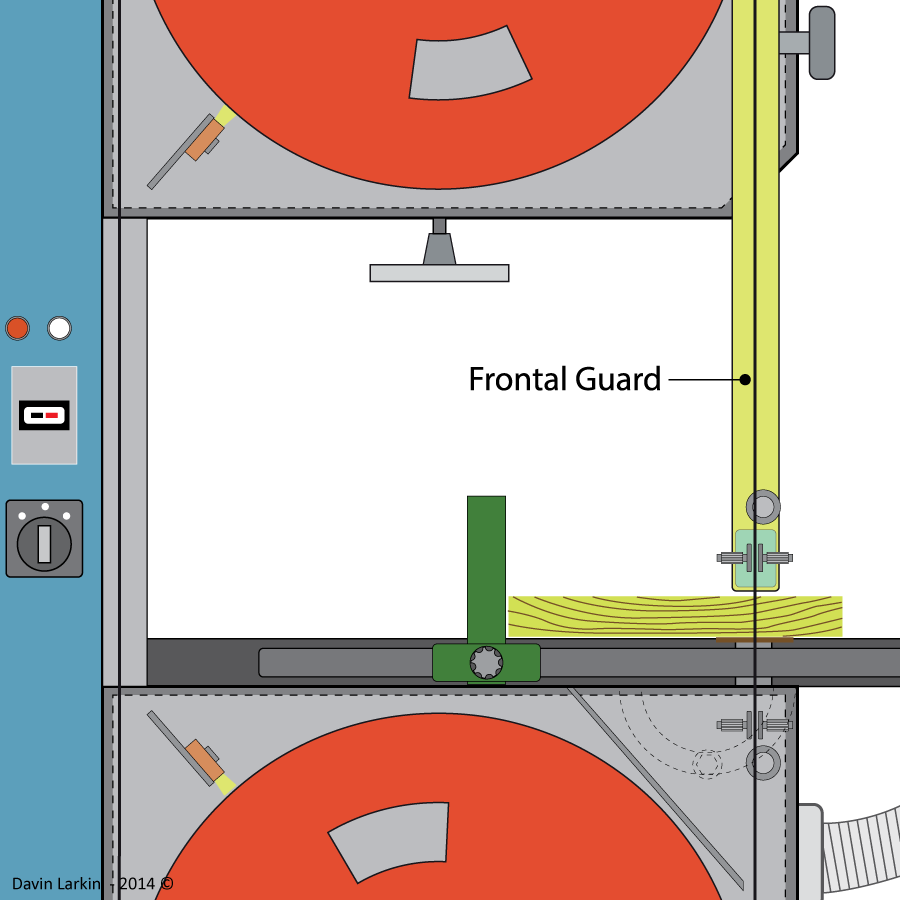

Adjust frontal guard as close as possible to the workpiece surface.

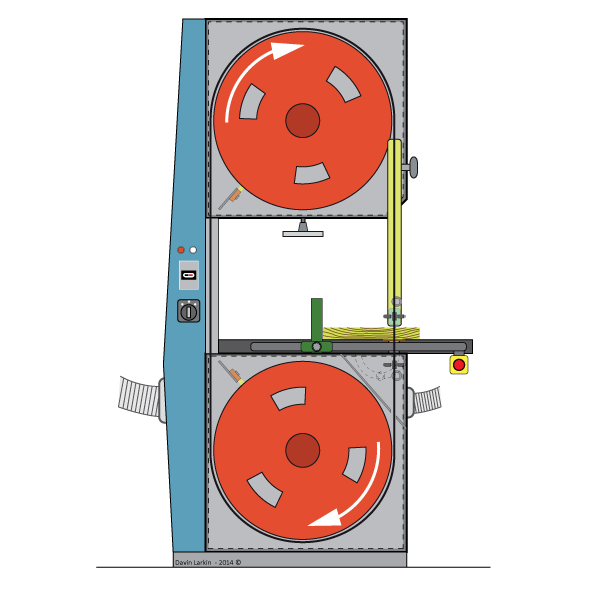

The pulley wheels and the extent of the blade, other than that part of the blade that runs downwards between the top wheel and the machine table, MUST be enclosed.

The blade MUST be guarded by a frontal guard which is as close as is practicable to the blade and has at least one flange at right angles to the plate that extends behind the saw blade.

The Narrow Band Saw saw MUST be braked and stop within 10 seconds.

If tension is relaxed than a permanent notice MUST be displayed to remind the next user to adjust the tension before starting the saw.

More information on the machine regulations can be found in the resource section below.