Safety

Woodworking machines are highly dangerous even in the hands of a skilled operator. In the interest of your safety it is important to wear Personal Protective Equipment (PPE) at all times when using this machine. Wearing the correct PPE can protect you from projectiles, noise, dust and many other elements.

You are advised to wear ear, eye and foot protection when using this machine.

If you want to learn more about PPE or the laws that require you to wear it, please visit one of the links below.

Personal Protective Equipment and Respiratory Protective Equipment

Publisher: Health & Safety Authority - IRL

Link: http://www.hsa.ie/eng/Topics/Personal_Protective_Equipment_-_PPE/

Personal protective equipment (PPE) at work

Publisher: Health & Safety Executive - UK

Link: http://www.hse.gov.uk/pubns/indg174.pdf

Safe Procedure

Before carrying out any setup or maintenance operations on this machine you MUST first isolate or knock off the electricity supply.

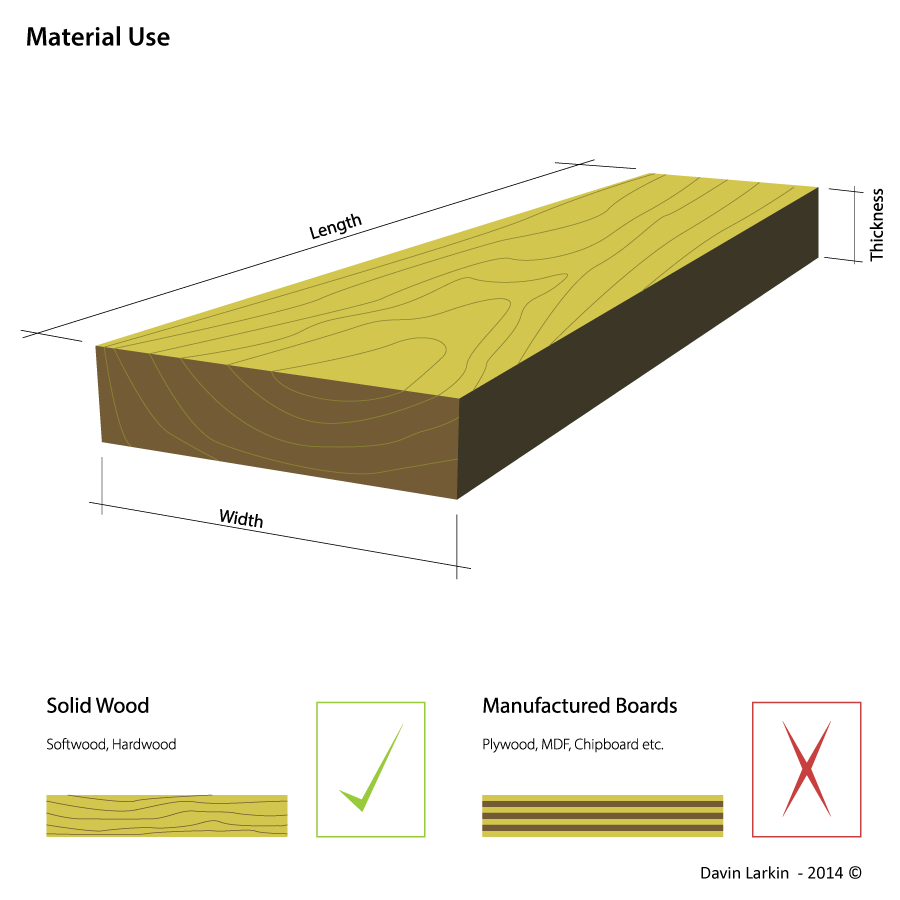

Materials

Length

WWrasp advises a minimum length of 400mm on this machine.

Width

The maximum width of material that can be cut is dependant on the width of the machine table.

Thickness

The maximum thickness of material varies from machine to machine. An average machine will range from 50-75mm (2-3 inches).

Materials

This machine is mainly used for ripping solid wood. WWrasp does not advice using manufactured boards on this machine.

If you need to rip manufactured boards WWrasp advices using a dedicated Dimension Saw or Panel Saw which has an enlarged machine table to cater for sheet material.

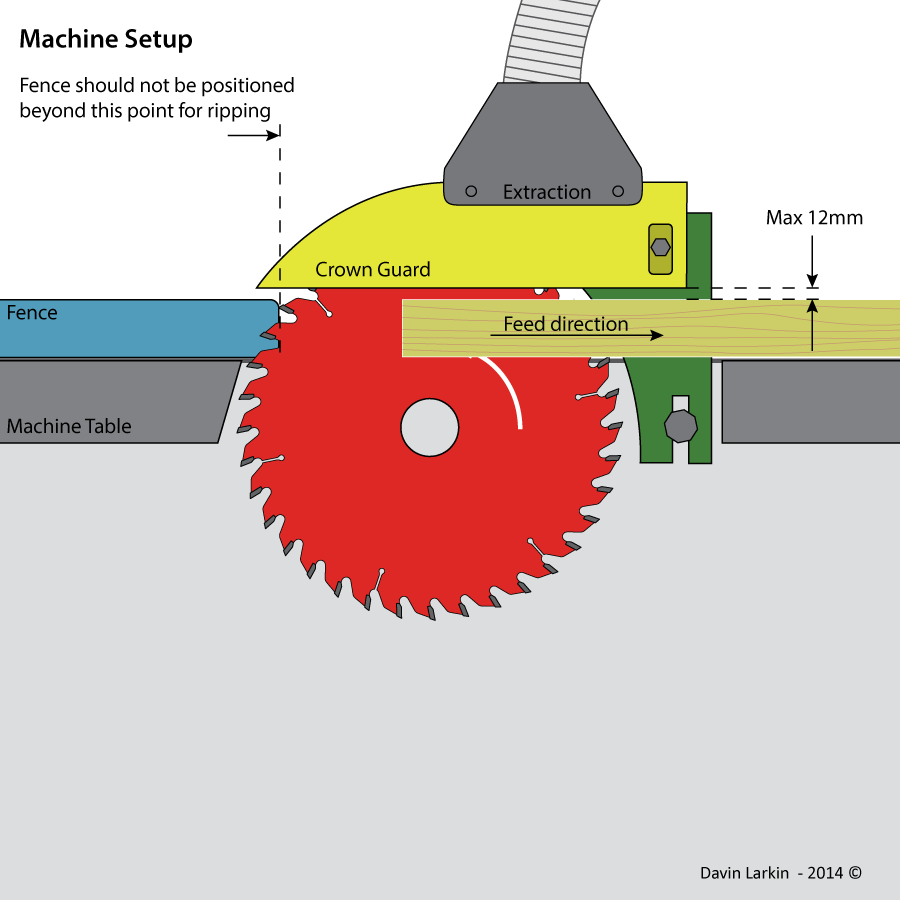

Setup

Before switching on the Rip Saw always:

- check the correct saw blade is fitted for the job you are about to undertake.

- adjust the blade to suit the height of the material being ripped.

- adjust the fence to the required width.

- adjust the fence to ensure it is inline with the first saw gullet at the machine table level.

- adjust the crown guard to a maximum distance of 12mm above the top surface of your material.

- make sure the riving knife is present and adjusted correctly.

- make sure the guard clears the full length of your material without any jams.

Material

Assess your material for twists, bows and cupping before machining to determine the correct orientation. Always keep the rounded face down to ensure it falls away from the blade when cut. If orientated with the rounded face up, it could bind or jam on the blade.

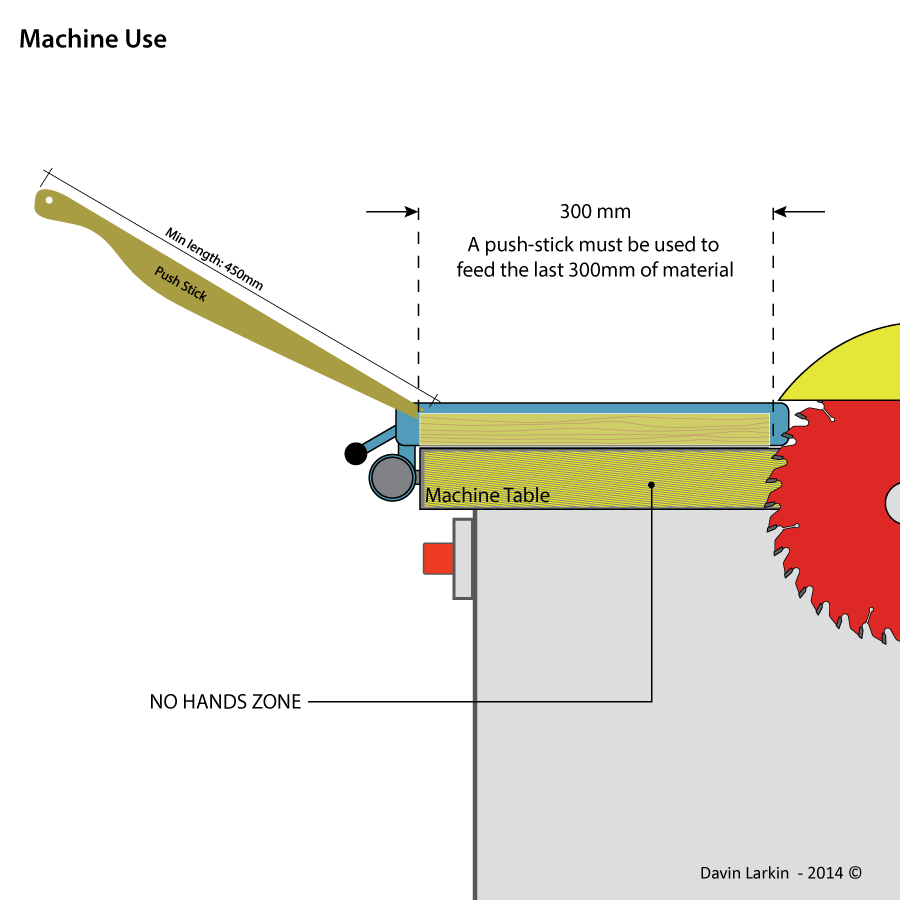

Push Stick

A push-stick MUST be available to feed the last 300mm of a cut and to remove off-cuts from the machine table.

Push-sticks should be at least 450mm long with a ‘bird’s mouth’. You will require two push-sticks to safely complete a ripping operation, one for the top of the material to help feed it and one for the edge to keep the material pressed against the fence.

Operation

During UsePlace your body out of line with the line of cut.

When feeding a long piece of material stand at the rear of the board and walk with it towards the machine rather than standing at the machine and feeding it through.

If your material is binding on the saw blade feed it in and out a few times to widen the saw cut, this will minimise the risk of the material binding on the saw blade.

If the saw is sharp, the timber will feed easily with little loss of saw speed however if excessive feeding pressure is used the wood may jerk or snatch. The sound the saw makes will tell you if it is blunt or being fed too fast, the pitch will lower if the saw slows down and the wood may also judder. If this happens partially withdraw the timber, allow the saw to gain speed, then feed it again more slowly.

If the saw blade is blunt, it should be changed.

Always use a push-stick to feed the last 300mm of timber.

NEVER PUT YOUR HANDS ON THE MACHINE TABLE OR IN THE LINE OF CUT FOR ANY REASON WHILE THE MACHINE IS RUNNING.

After Use

Switch OFF the machine when finished or when leaving the machine temporarily.

Regulations

The saw blade is required to be guarded both above and below the machine table.

Adjust the Crown guard to be no more than 12mm from the top surface of the workpiece.

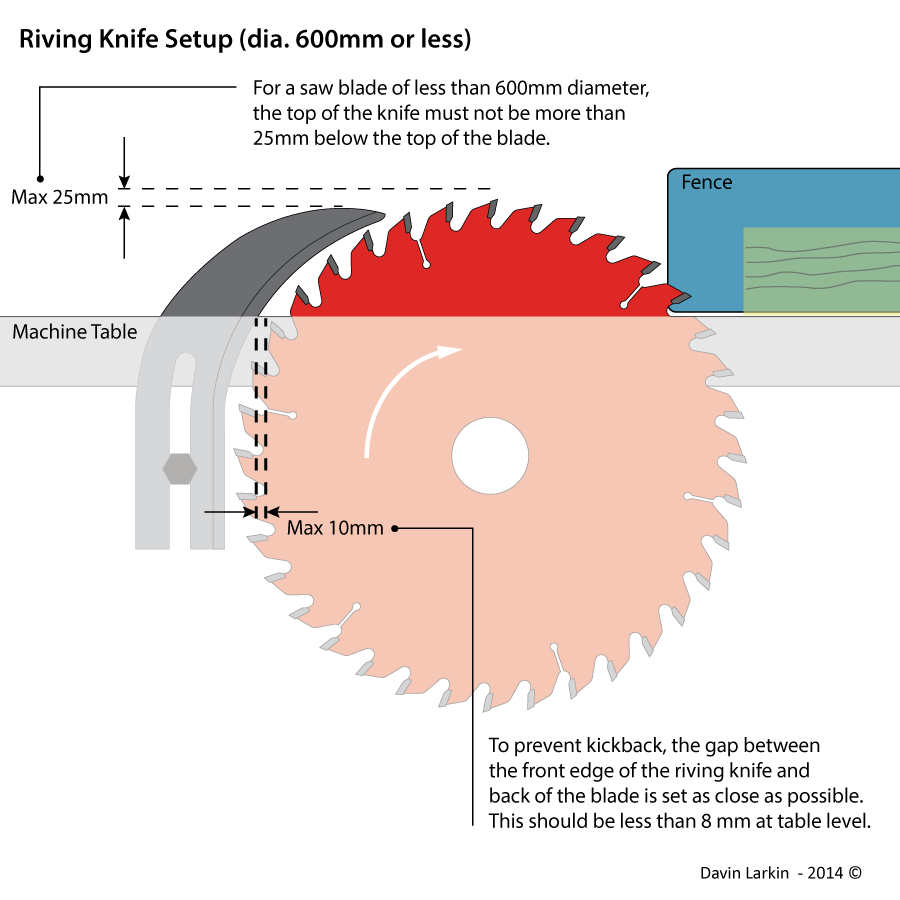

For a saw blade of less than 600mm diameter, the top of the knife must not be more than 25mm below the top of the blade. For a saw blade of 600mm diameter or more, the top of the knife must be at least 225mm above the table.

To prevent kickback, the gap between the front edge of the riving knife and back of the blade is set as close as possible. This should be less than 8mm at table level.

The smallest blade that can be fitted is 60% (6/10) of the largest diameter saw blade the saw is designed to use.

The circular saw MUST be braked and stop within 10 seconds.