Safety

Woodworking machines are highly dangerous even in the hands of a skilled operator. In the interest of your safety it is important to wear Personal Protective Equipment (PPE) at all times when using this machine. Wearing the correct PPE can protect you from projectiles, noise, dust and many other elements.

You are advised to wear ear, eye and foot protection when using this machine.

If you want to learn more about PPE or the laws that require you to wear it, please visit one of the links below.

Personal Protective Equipment and Respiratory Protective Equipment

Publisher: Health & Safety Authority - IRL

Link: http://www.hsa.ie/eng/Topics/Personal_Protective_Equipment_-_PPE/

Personal protective equipment (PPE) at work

Publisher: Health & Safety Executive - UK

Link: http://www.hse.gov.uk/pubns/indg174.pdf

Safe Procedure

Before carrying out any setup or maintenance operations on this machine you MUST first isolate or knock off the electricity supply.

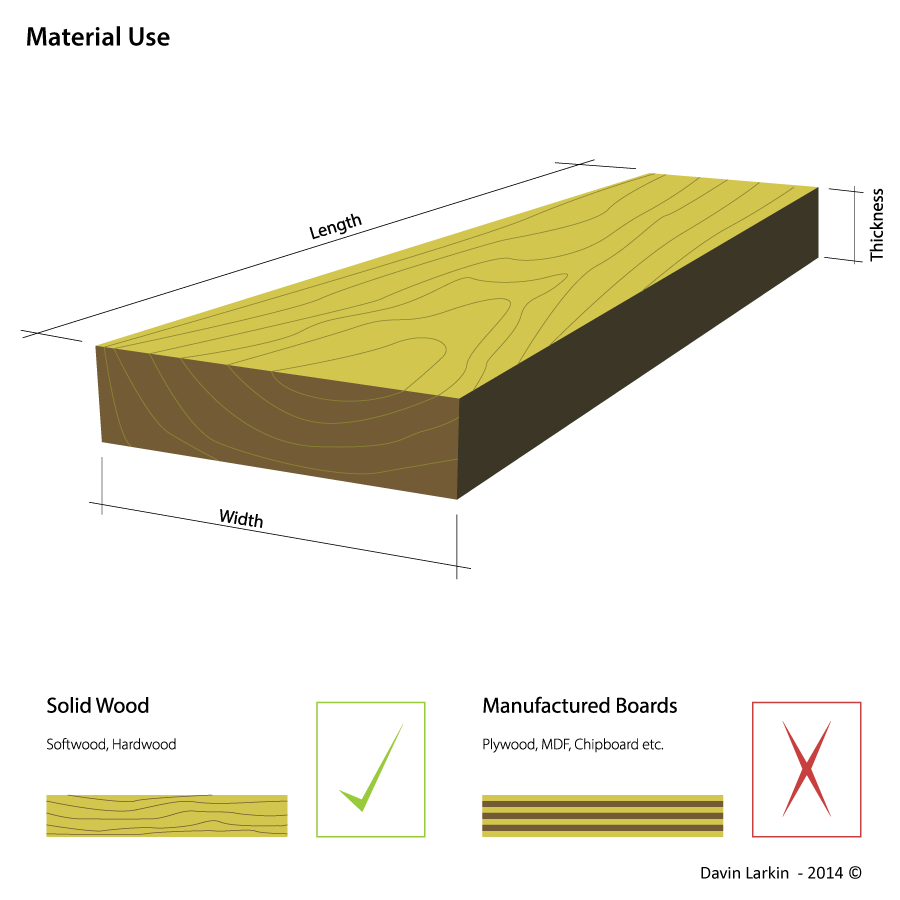

Materials

Length

WWrasp advises planing a minimum length of 350mm on this machine.

Width

The maximum width of material that can be cut is dependant on the width of the machine table. It can be easily determined by moving the fence to rear of the machine table and measuring the length of the cutters within the cutterblock.

Materials

This machine is mainly used for planing solid wood. WWrasp does not advice using manufactured boards on this machine as it will blunt the cutters at a much faster rate than solid wood.

If you need to plane manufactured boards use a part of the cutterblock that is not often used to ensure it will not effect future planing operations.You may also wish to install Tungsten Carbide Tipped (TCT) cutters as opposed to High Speed Steel (HSS) cutters which are more resistant to the glues and resins present in manufactured boards.

Setup

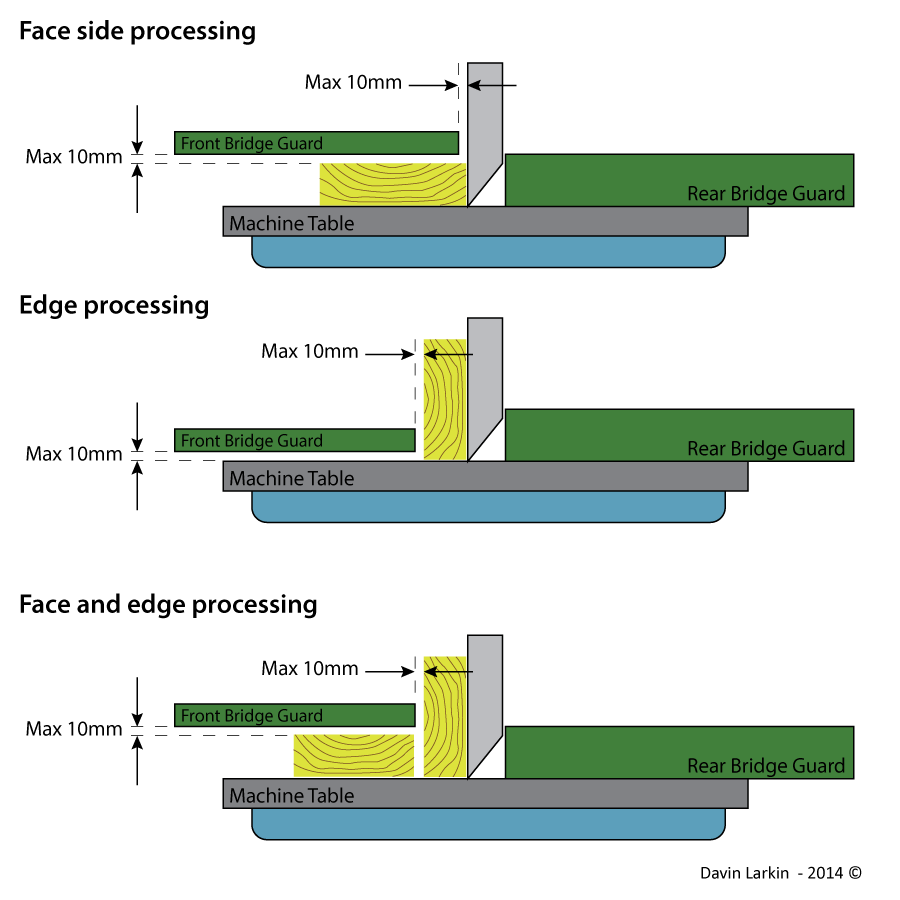

Before switching on the Surface Planer always:

- adjust the fence to suit the width of material being planed

- Adjust the infeed table to the cutting depth required

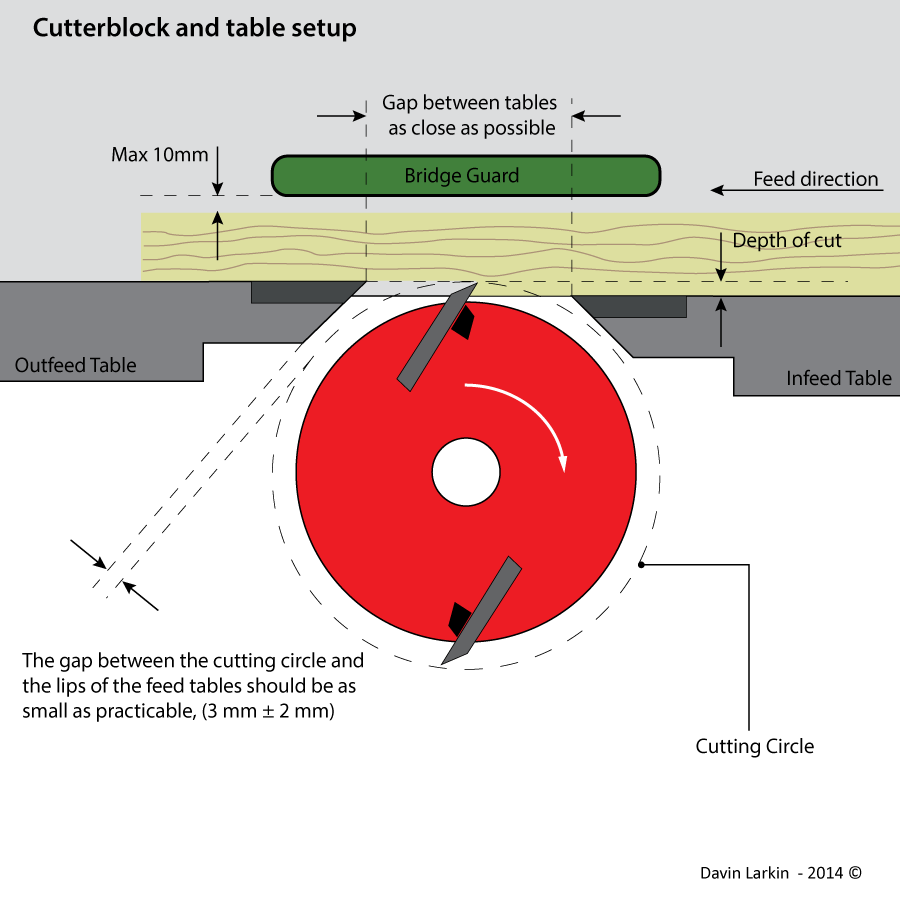

- adjust the bridge guard as close as possible to the material being planed and no more then 10mm away

Depth of cut

For narrow boards, less than 100mm wide, the maximum advised depth of cut is 2-3mm with each pass.A 1-2mm depth of cut should be sufficient for most jobs.

For wide boards, more than 100mm wide, the maximum advised depth of cut is 1mm with each pass.

Material

Assess your material for twists, bows and cupping before machining to determine the correct orientation and where possible always machine with the grain.

If a board is bowed or cupped, place the hollow side down on the machine table. This will minimise the risk of the board see-sawing as feed pressure is altered.

If a board is twisted or distorted find the orientation where the timber naturally rests and feed it through without rocking or disturbing its position until a consistent flat face is formed.

Operation

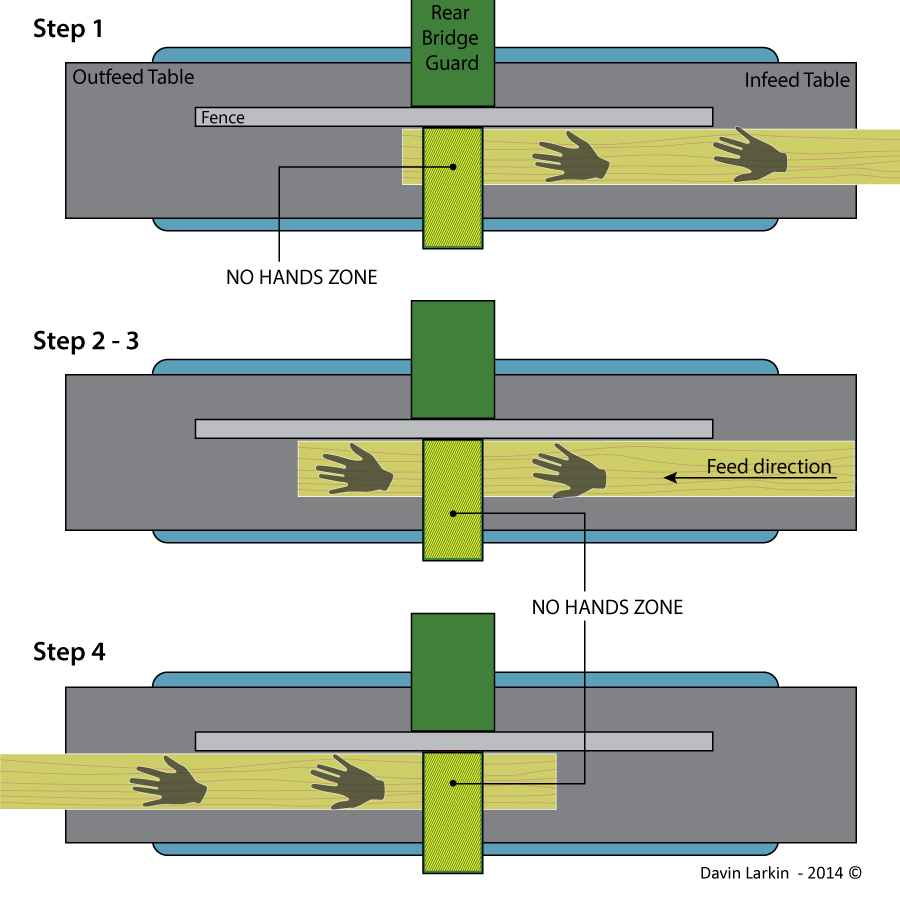

During UseAlways plane the face first, and edge second.

Step 1: Use light pressure with both hands placed on the board as it is fed into the cutters.

Step 2: As the timber passes over the cutterblock and lands on the outfeed table lift your forward hand over the bridge guard, it is not safe to slide it over the bridge guard, it should be lifted over the timber to minimize the risk of an accident.

Step 3: Place your forward hand on the timber on the outfeed table while continuing to feed with your rear hand. Keep feeding until only 300mm of your material is left on the infeed table.

Step 4: At this point lift your rear hand to the material on the outfeed table and continue feeding until complete. Feed the materiel at a steady pace to reduce the risk of pitch marks.

Wide boards (in excess of 100mm wide) should be fed at a slight angle to the fence for face planing to reduce the initial impact and risk of kickback.

After Use

Switch OFF the machine when finished or when leaving the machine temporarily.

If material is sticking or was difficult to push, apply some wax or spray lubricant to reduce friction on the machine table.

Regulations

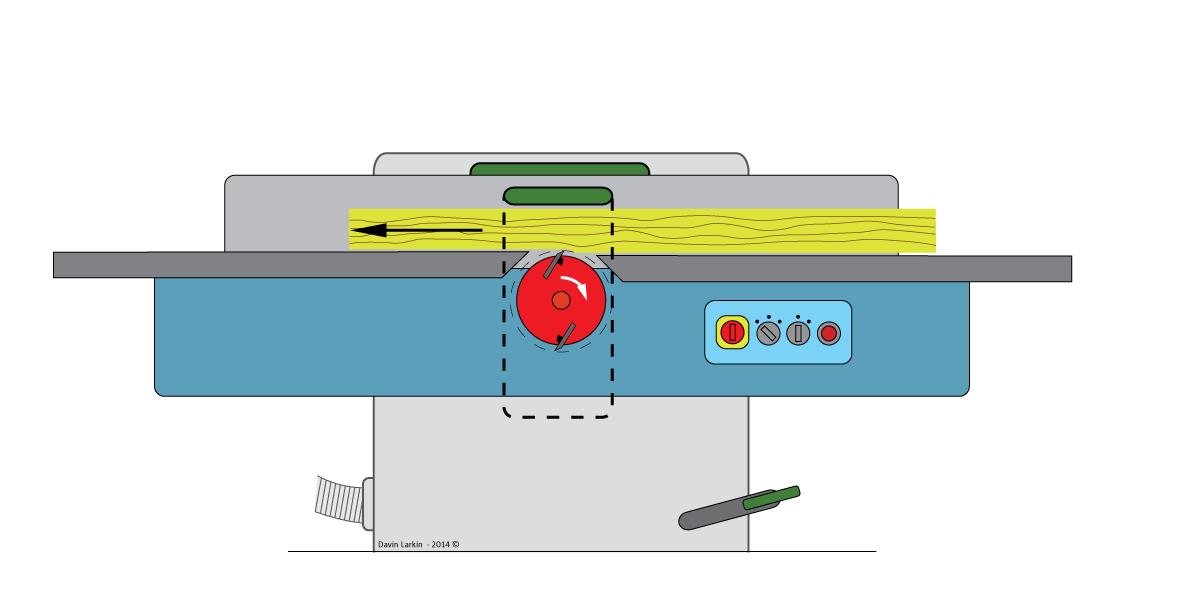

Only cylindrical (or ‘round form’) cutter blocks should be used on handfed planing machines. The maximum cutter projection should be 1.1 mm(BS EN 8471).

The clearance distance between the cutting circle and the lips of the infeed and outfeed tables should be as small as practicable, generally 3 mm ± 2 mm. The outfeed table height should never be below the cutting circle diameter.

A bridge guard must be strong and rigid, have a length not less than the full length of the cutter block and a width no less than the diameter of the cutter block and is constructed so as to be capable of easy adjustment in both a vertical and horizontal direction.

The under surface OR the end of the bridge guard cannot be more then 10mm from the surface of the material being machined.

A rear guard MUST be permanently fitted to the back surface of the fence to prevent the operator from coming into contact with the blades as the fence is adjusted across the machine table.

The Surface Planer MUST be braked and stop within 10 seconds.