Safety

Woodworking machines are highly dangerous even in the hands of a skilled operator. In the interest of your safety it is important to wear Personal Protective Equipment (PPE) at all times when using this machine. Wearing the correct PPE can protect you from projectiles, noise, dust and many other elements.

You are advised to wear eye, hand and foot protection when using this machine.

If you want to learn more about PPE or the laws that require you to wear it, please visit one of the links below.

Personal Protective Equipment and Respiratory Protective Equipment

Publisher: Health & Safety Authority - IRL

Link: http://www.hsa.ie/eng/Topics/Personal_Protective_Equipment_-_PPE/

Personal protective equipment (PPE) at work

Publisher: Health & Safety Executive - UK

Link: http://www.hse.gov.uk/pubns/indg174.pdf

Safe Procedure

Before carrying out any setup or maintenance operations on this machine you MUST first isolate or knock off the electricity supply.

Materials

Size

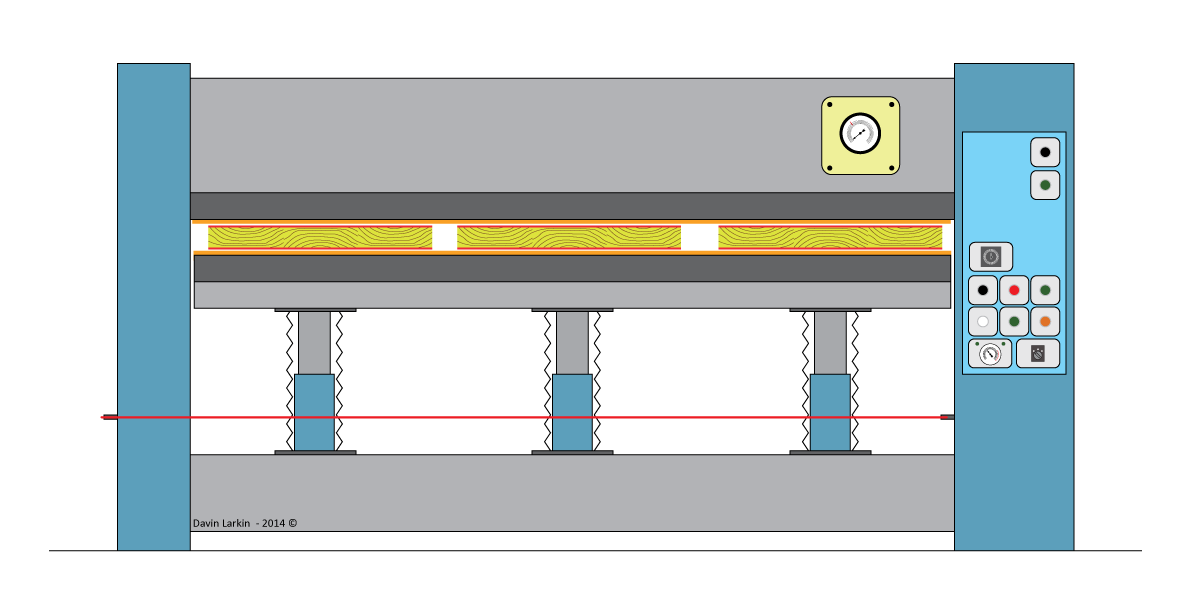

The maximum panel size on most workshop machines is 2440 x 1220mm. Many variations of this machine exist with smaller and larger capabilities. Measure the Platen surface area to see what the maximum panel size is on your machine.

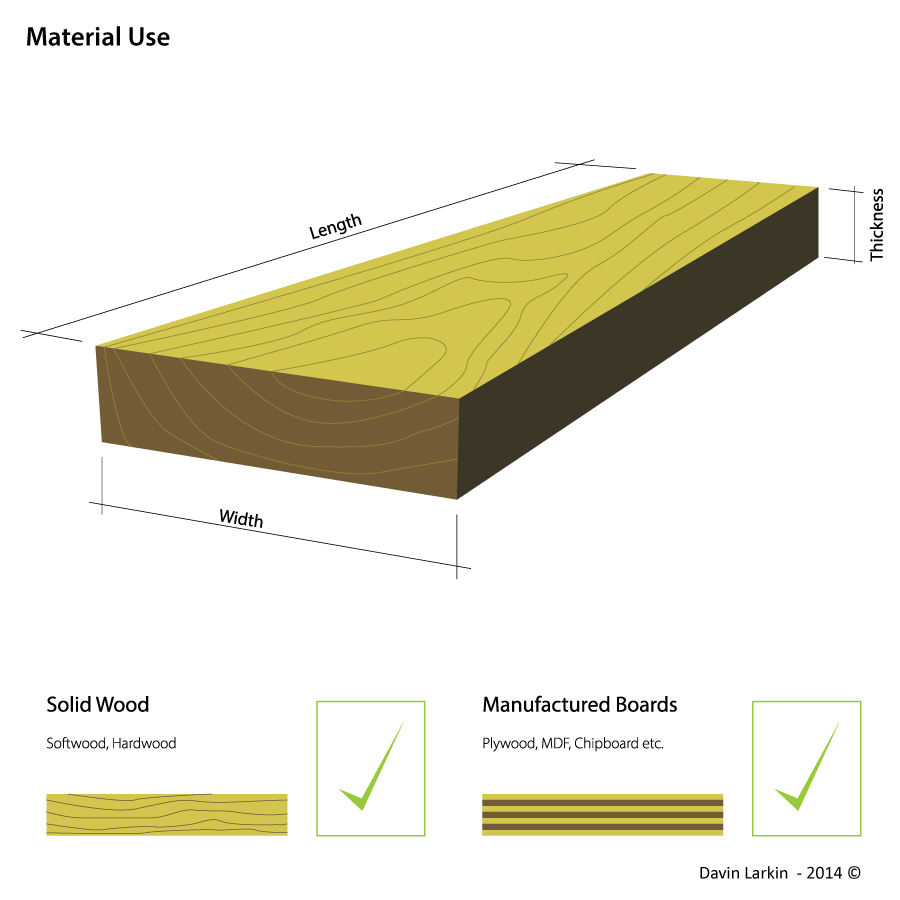

Materials

This machine is used for veneering or laminating flat panels.The majority of work on this machine will be with manufactured boards. The manufactured board, usually MDF, Plywood or Chipboard is known as the substrate or core. The veneer or laminate is then applied to this material.

The benefits of using manufactured boards for veneering and lamination is the minimal wood movement that occurs in comparison to solid wood. If you use solid wood as your core material there is a much higher risk of the veneer splitting or cracking over time.

Setup

Before placing your materials in the veneer press:

- ensure you have all your materials to hand and someone to help if you have a large number of panels to veneer

- make sure an even layer of glue has been applied to the entire substrate material before your veneer or laminate is applied

- if your veneer press has heated platens make sure they have been preheated before using the machine

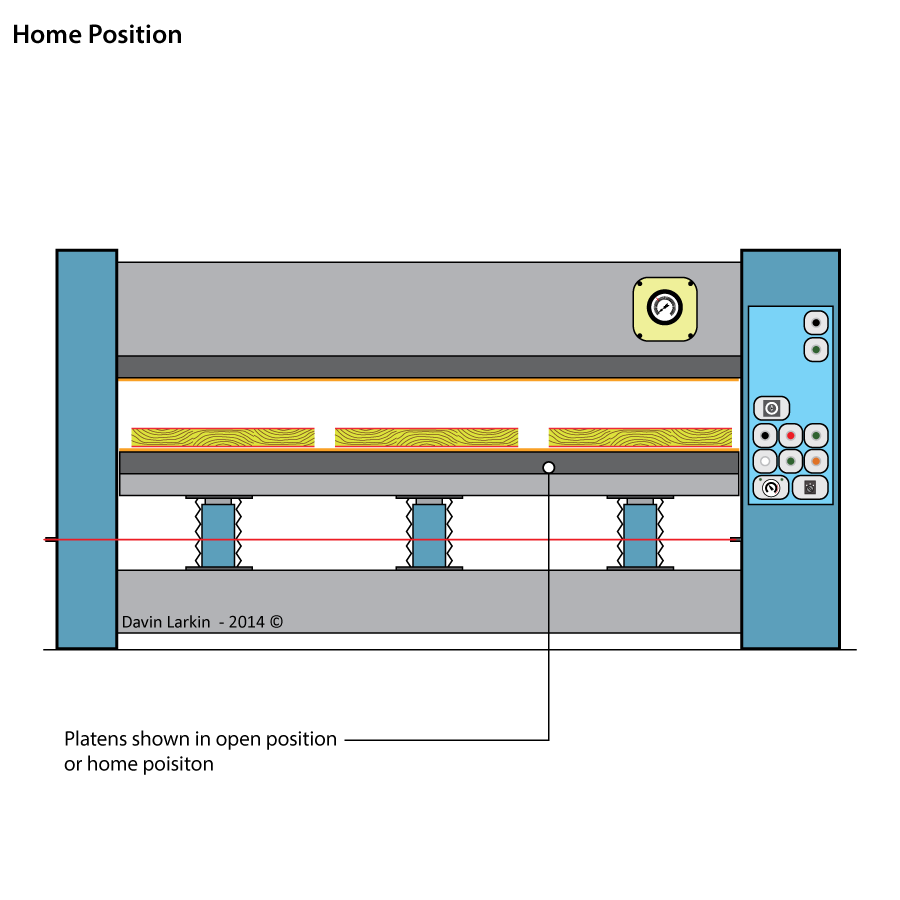

- when your materials are ready open the platens and place your material as described below

- once your material is placed in the machine, close the platens and set the timer according the curing time of your selected glue

Material Placement

During the positioning of your material in the press, use protective gloves, as the platens can reach high temperatures.

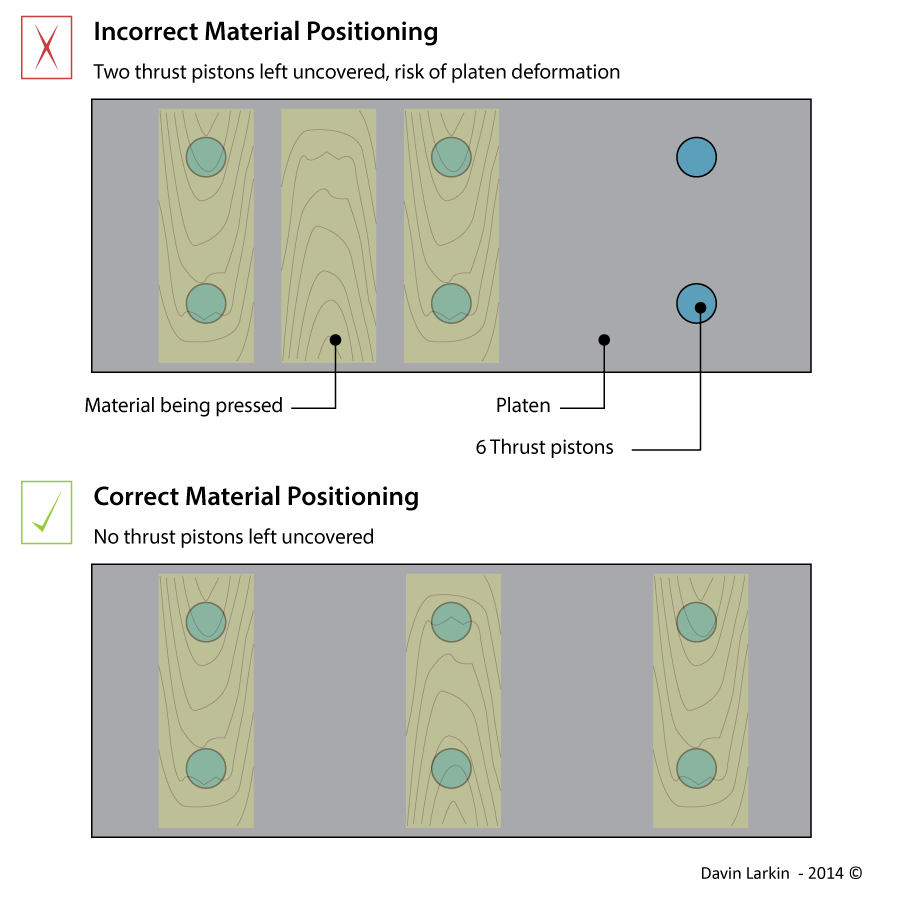

Arrange your materials in the press in such a way as to involve all the thrust pistons. You must not leave any thrust piston blank as on closing it could buckle or distort the platen.

When there is not enough material available to cover all thrust pistons, materials of the same thickness be used in these positions to prevent deformation of the platens.

You may place multiple panels of the same thickness in the veneer press side by side for large volume pressing operations.

Operation

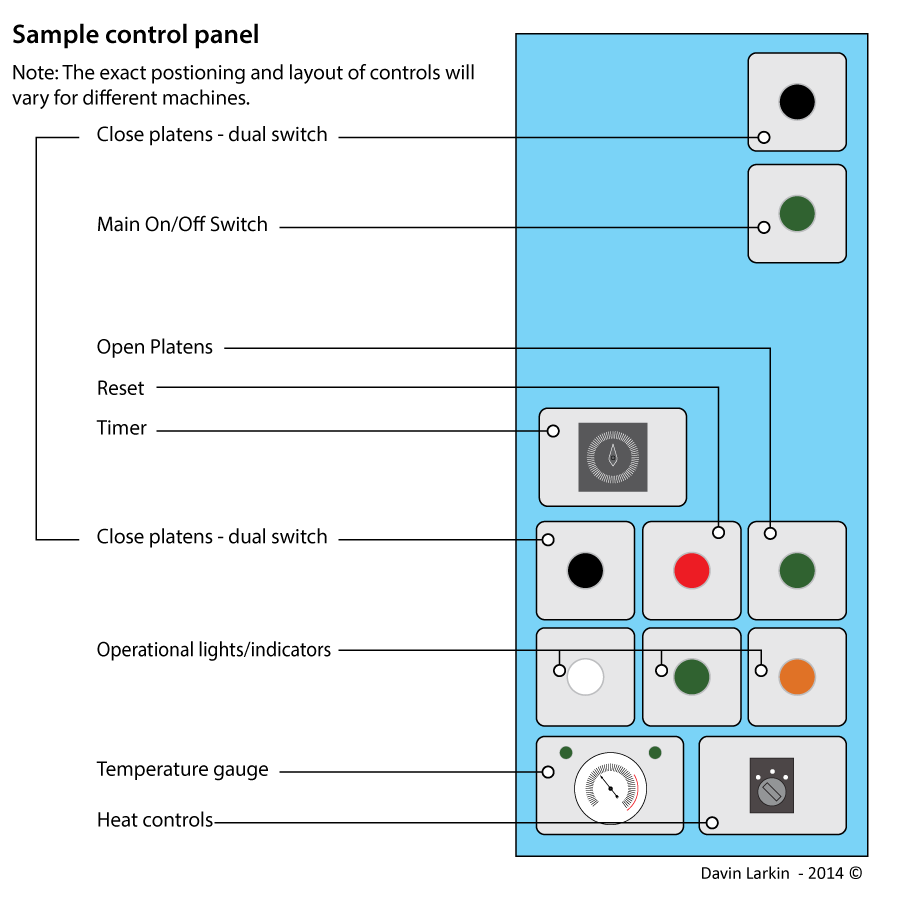

During UseOnce the platens are closed ensure they are set to the correct pressure for the material being pressed, the temperature is set correctly and a timer has been set.Veneer presses use two types of timers.

Automatic opening: The pressing time is set at the start of each pressing operation, using the minute counter with buzzer. When the time is up the platens will automatically open and begin to cool down.

Non-Automatic opening: As above but when the time is up the buzzer will sound and the machine will begin to cool down but the platens will have to be opened manually.

WWrasp advices you to place a sheet of thin manufactured board (9mm) and a layer of plastic sheet above and below your material. This protects the platens from any damage from foreign object or glue squeeze out that may occur during pressing. The plastic is placed directly above and below the material being pressed and should not come in contact with the hot platens.

After Use

Switch OFF the machine when finished and leave the platens in the open position so other users are aware it is not currently in use.

Regulations

WWrasp advises the following when using this machine:

All manoeuvres during the closing of the press are prohibited due to the possibility of crush injuries.

This machine has being designed to be closed by one operator only, some machine utilise a dual closing switch where two hands are required for safety reasons to guarantee operator safety during the dangerous closure movement.

The operations of loading and unloading of the material must be completed only when the pattens are lodged in their open position.