Safety

Woodworking machines are highly dangerous even in the hands of a skilled operator. In the interest of your safety it is important to wear Personal Protective Equipment (PPE) at all times when using this machine. Wearing the correct PPE can protect you from projectiles, noise, dust and many other elements.

You are advised to wear ear, eye and foot protection when using this machine.

If you want to learn more about PPE or the laws that require you to wear it, please visit one of the links below.

Personal Protective Equipment and Respiratory Protective Equipment

Publisher: Health & Safety Authority - IRL

Link: http://www.hsa.ie/eng/Topics/Personal_Protective_Equipment_-_PPE/

Personal protective equipment (PPE) at work

Publisher: Health & Safety Executive - UK

Link: http://www.hse.gov.uk/pubns/indg174.pdf

Safe Procedure

Before carrying out any setup or maintenance operations on this machine you MUST first isolate or knock off the electricity supply.

Materials

Length

WWrasp advises a minimum safe length of 800mm when using this machine.This is to limit the risk of kickback from the fence which is much more difficult to control in short lengths.

Depth of Cut

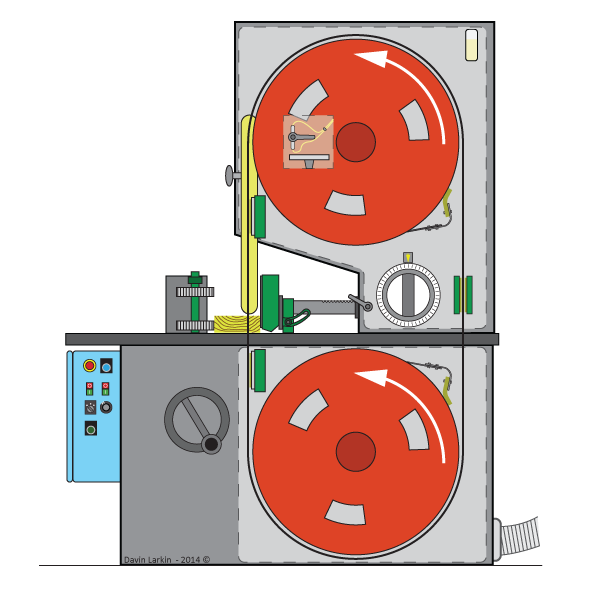

Most Band Re-Saws will process material up to a depth of 200mm while large machines can manage depths of cut of up to 400mm. Check the machine capabilities before processing large stock, in excess of 100mm.

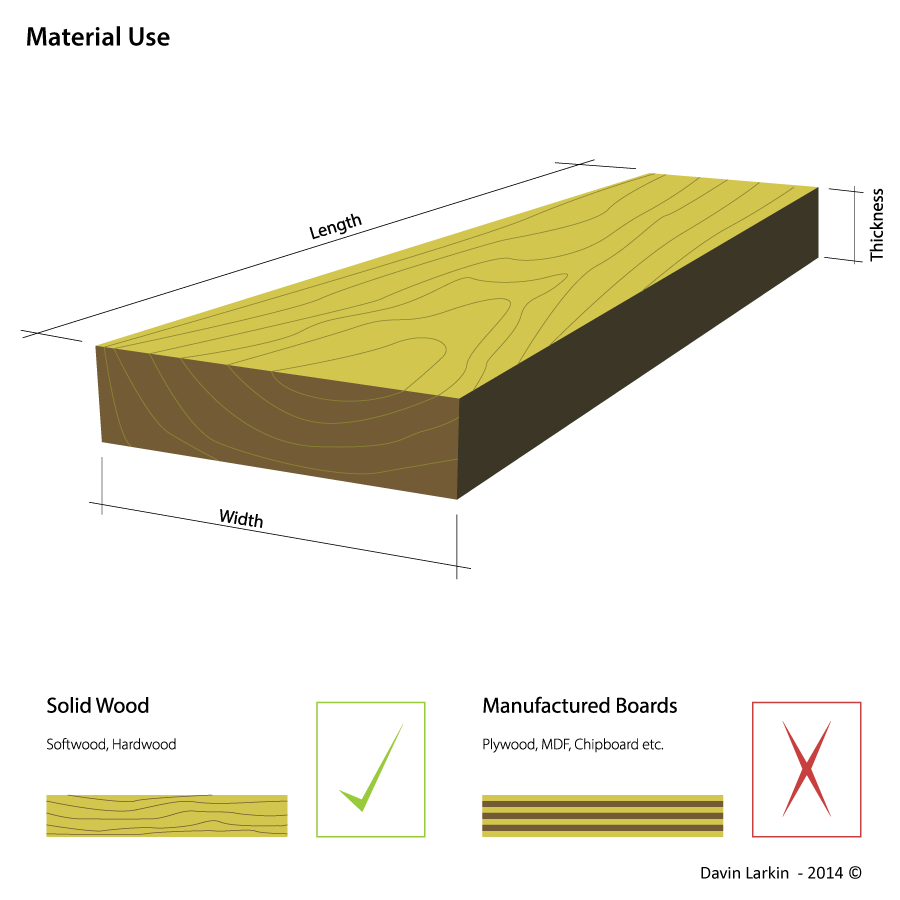

Materials

This machine is used for cutting solid wood only.

All material to be processed on this machine should have at least one straight, flat face which should be presented against the fence.

Setup

Before switching on the Band Re-Saw always:

- check the correct saw blade is fitted for the job you are about to undertake

- ensure the saw blade is in tension

- turn on the drip feed system to ensure the cleaning pads are lubricated

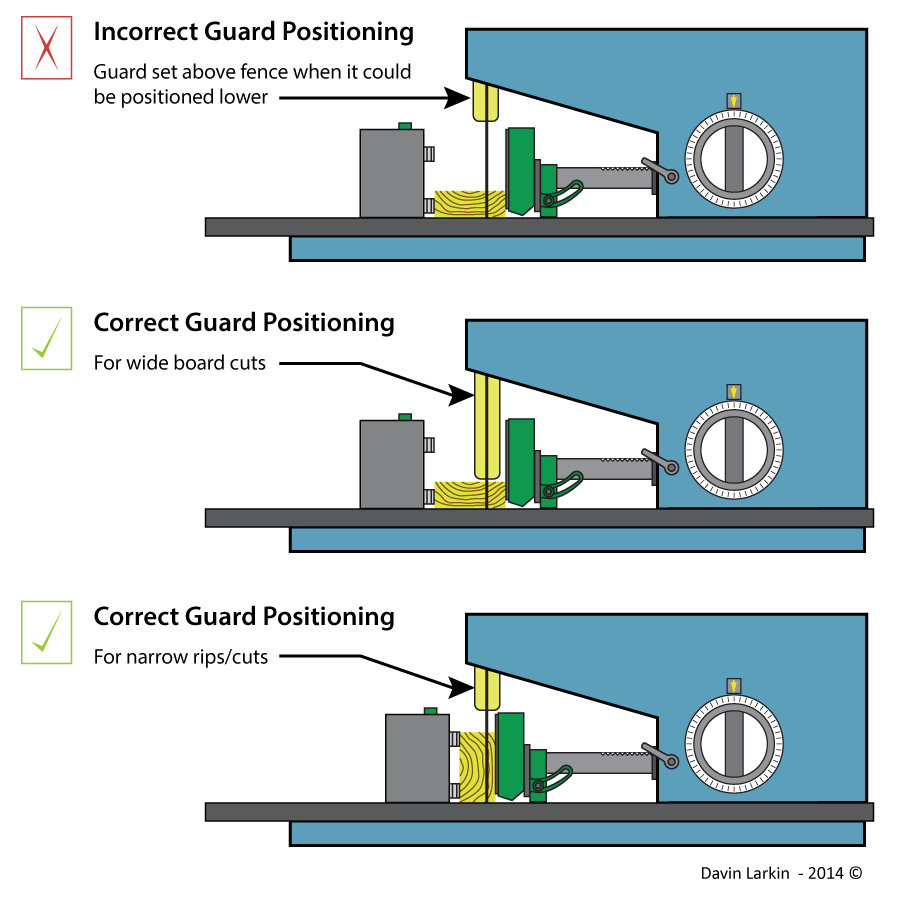

- adjust the guard as close as possible to the workpiece. If the guards can be lowered between the feed rollers and fence, without any chance of fouling either, then the guard should be set to 20mm above the workpiece surface

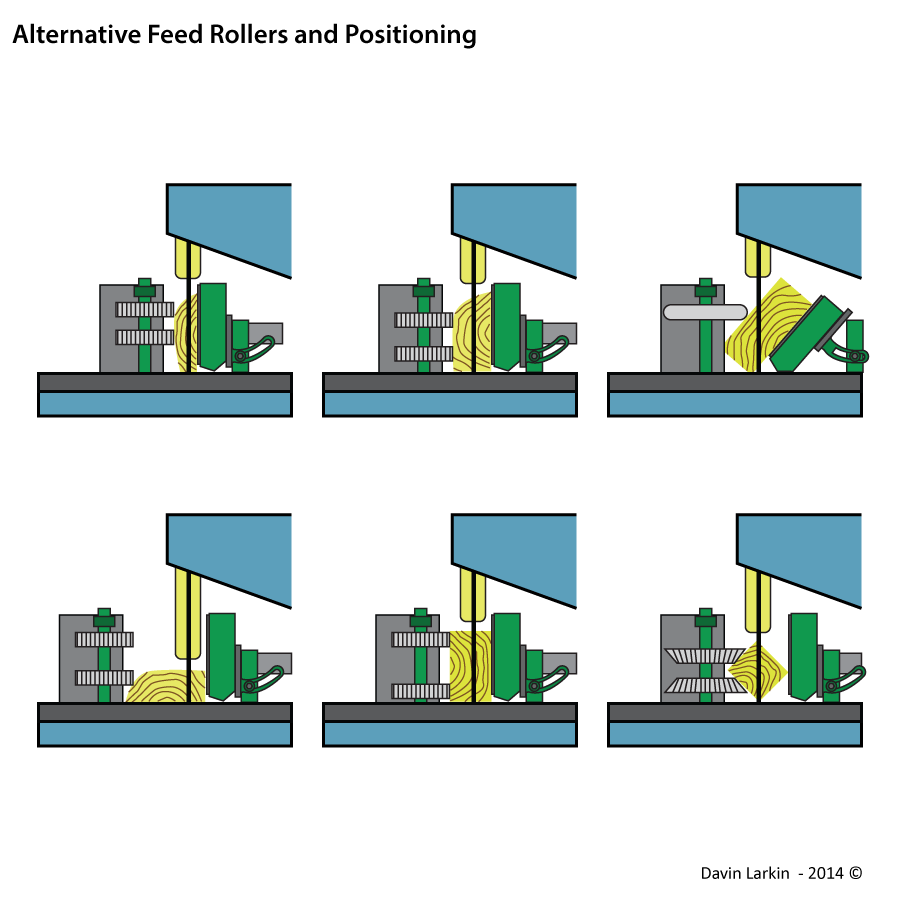

- position the feed rollers according to the material being processed. The gap between the fence and feed rollers should be smaller than the thickness of the timber to be cut so that the rollers climb the timber and are pushed back when cutting, thus maintaining pressure on the timber. The rollers will generally not climb more than 50 mm

- set the feed speed according to the material being processed. Feed speeds generally range from 5m/min to up to 60m/min

- after switching on the machine wait until it is running at full speed before switching on the feed rollers

This machine is for straight cutting only, curved or scroll cutting should not be attempted on this machine.

Operation

During UsePlace your body out of line with the line of cut.

Place you material with the flat face or straight edge against the fence, feed it into the machine until the feed unit takes hold of the material. At this point let the machine control the feed but make sure you hold the weight of the material to eliminate the risk of it tipping off the machine table under its own weight.

When feeding a long piece of material stand at the rear of the board and walk with it towards the machine rather than standing at the machine and feeding it through.

Angled cutting can be performed either by special jigs and/or feed rollers or by tilting the fence and using a rubber covered feed roller.

If an operator is removing stock from the rear of the machine an extension table must be fitted with a minimum length of 1200mm.

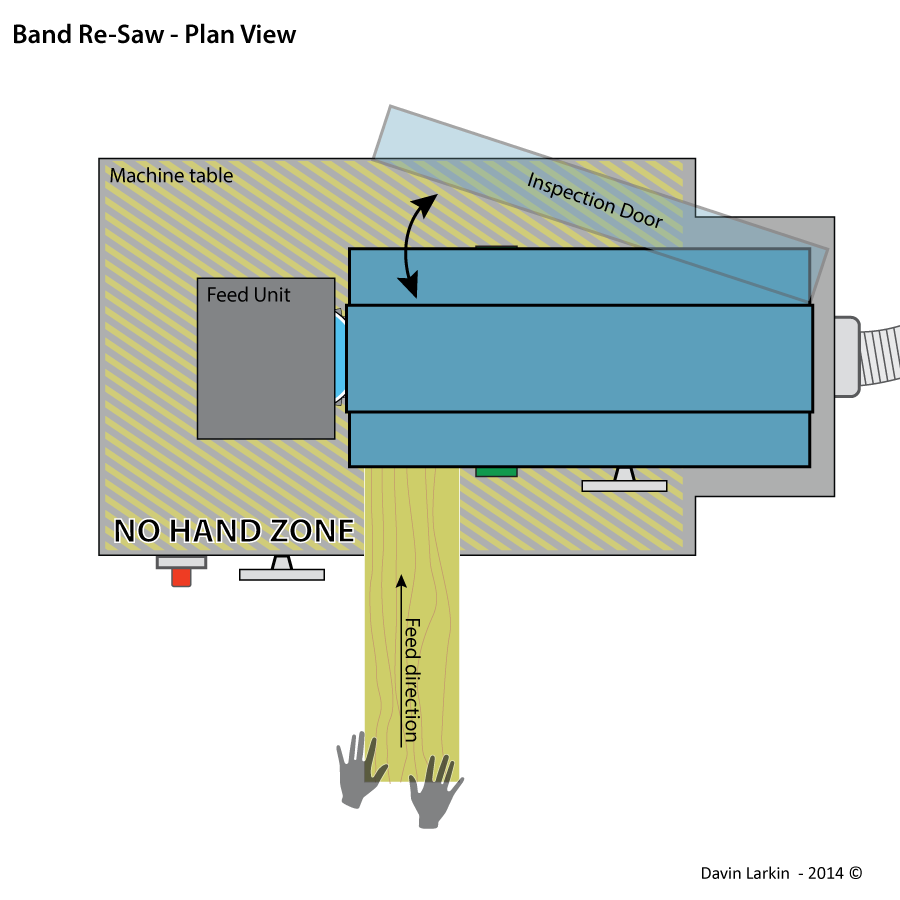

NEVER PUT YOUR HANDS ON THE MACHINE TABLE FOR ANY REASON WHILE THE MACHINE IS RUNNING.

WWrasp considers the entire machine table a NO HANDS ZONE.

After Use

Switch OFF the machine when finished, or when leaving the machine temporarily. Wait until the machine has come to a full stop before leaving it or attempting to setup the machine for further operations.

Regulations

Adjust frontal guard as close as possible to the workpiece surface.

The pulley wheels and the extent of the blade, other than that part of the blade that runs downwards between the top wheel and the machine table, MUST be enclosed.

The blade MUST be guarded by a frontal guard which is as close as is practicable to the blade and has at least one flange at right angles to the plate that extends behind the saw blade.

The Band Re-Saw MUST be braked and stop within 10 seconds.

The feed unit enclosure/guard MUST remain in place at all times.

The guard should NEVER be adjusted whilst the machine is running.

More information on the machine regulations can be found in the resource section below.