Safety

Woodworking machines are highly dangerous even in the hands of a skilled operator. In the interest of your safety it is important to wear Personal Protective Equipment (PPE) at all times when using this machine. Wearing the correct PPE can protect you from projectiles, noise, dust and many other elements.

You are advised to wear ear, eye and foot protection when using this machine.

If you want to learn more about PPE or the laws that require you to wear it, please visit one of the links below.

Personal Protective Equipment and Respiratory Protective Equipment

Publisher: Health & Safety Authority - IRL

Link: http://www.hsa.ie/eng/Topics/Personal_Protective_Equipment_-_PPE/

Personal protective equipment (PPE) at work

Publisher: Health & Safety Executive - UK

Link: http://www.hse.gov.uk/pubns/indg174.pdf

Safe Procedure

Before carrying out any setup or maintenance operations on this machine you MUST first isolate or knock off the electricity supply.

Materials

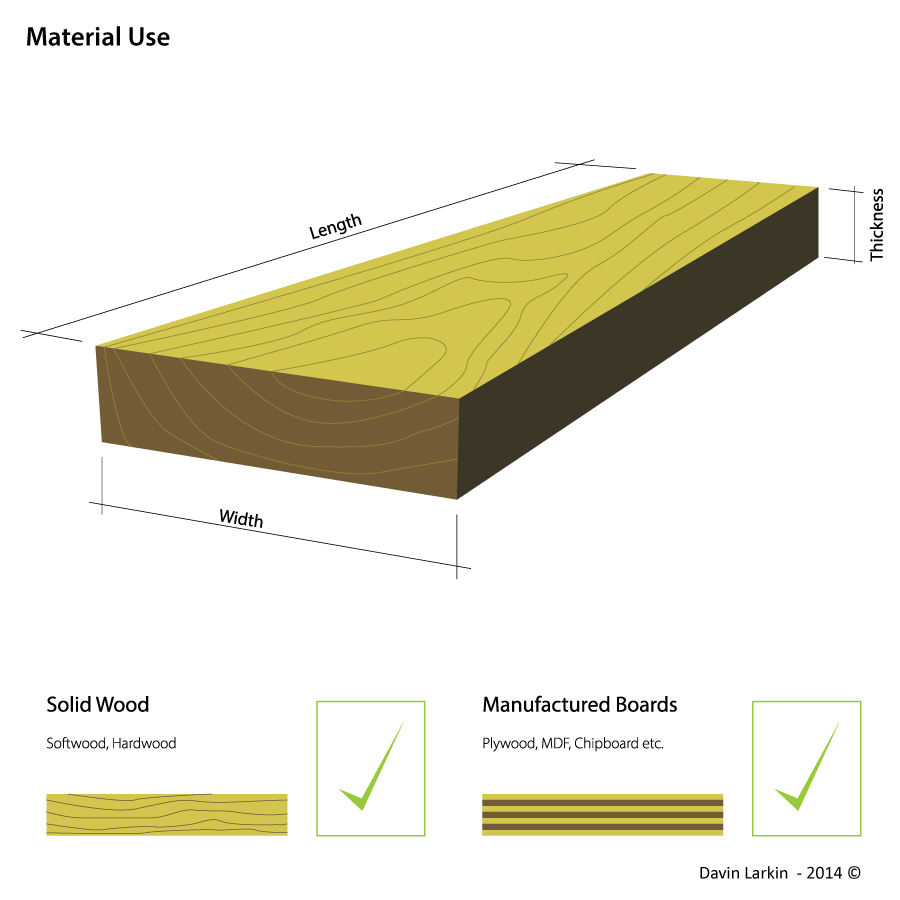

Thickness

The maximum thickness a cross cut saw is capable of cutting through ranges from 50mm to 150mm. On average the maximum thickness is 75mm. this dimensions is determined by the diameter of blade that is fitted to the machine.

Width

The maximum width of material that can be cut is dependant on the length of the radial arm. It can be easily determined by moving the saw unit to the end of the radial arm and measuring the distance between the saw blade and machine fence.

Materials

This machine is mainly used for cutting solid wood. It can also be used for cutting manufactured boards.

Setup

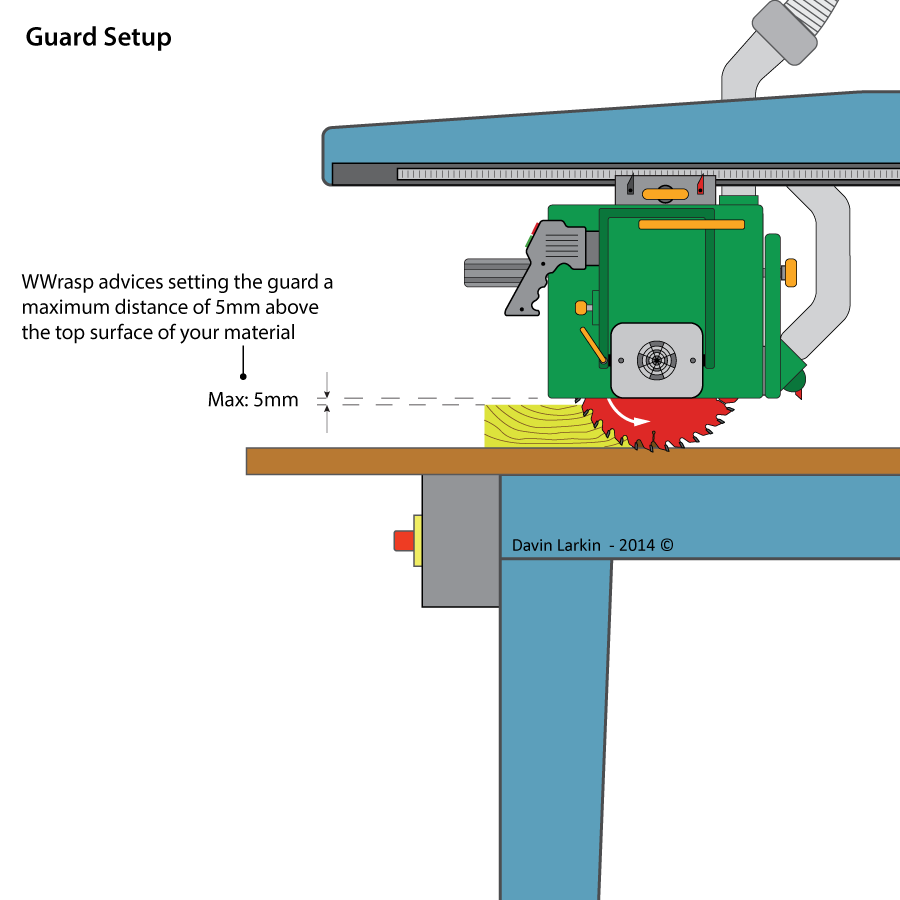

Before switching on the Cross Cut Saw always:

- check the correct saw blade is fitted for the job you are about to undertake.

- adjust the guard to a maximum distance of 5mm above the top surface of your material.

- make sure the guard clears the full width of your material without any jams.

Material

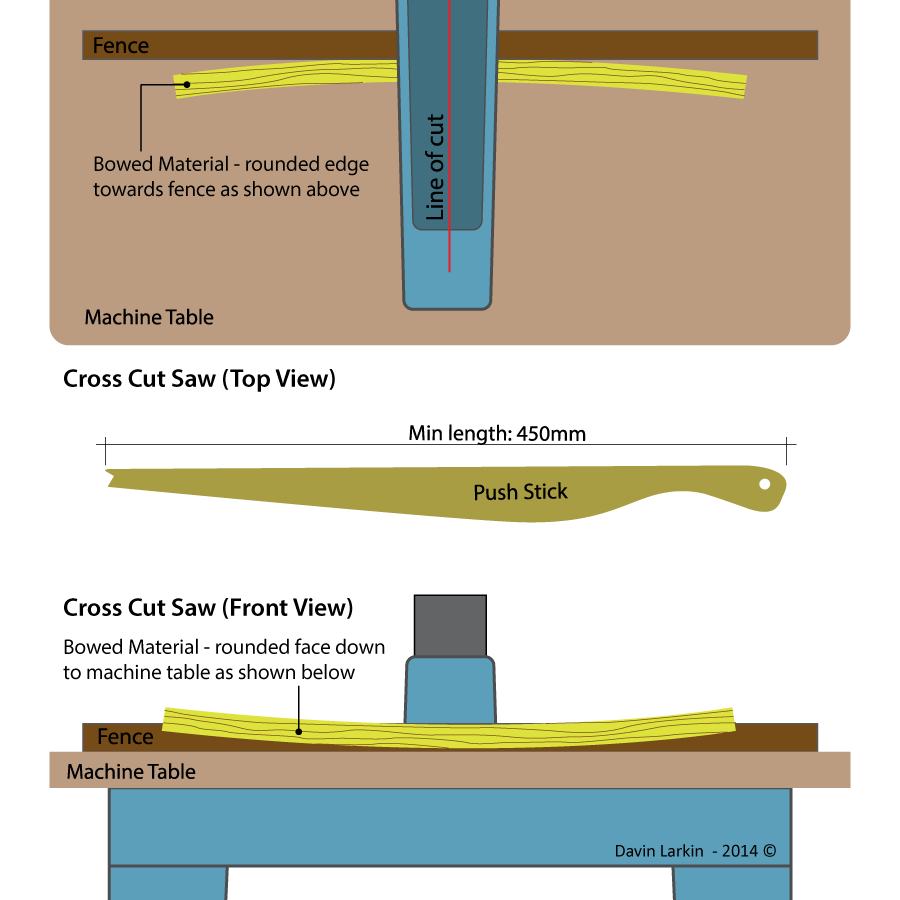

Assess your material for twists, bows and cupping before machining to determine the correct orientation. Bowed material should be placed bow down against the machine table and bowed edge towards the fence as shown in image.

If your board material is over 2.5 metres long or very heavy ask for help, when the board is cut, it could fall off the table under its own weight and cause an accident.

Push Stick

A push-stick MUST be available to remove off-cuts from the machine table.

Push-sticks should be at least 450mm long with a ‘bird’s mouth’

Operation

During UseWWrasp advise cross cut operators to keep thumbs close to your hand - not extended.

Place your body to the left or right of the machine, out of line with the line of cut.

Use one hand to hold your material and one to control the saw unit.

Ease the saw unit forward into the material, complete your cut in multiple passes, ease it in and out of the cut. If you try to complete the cut in one pass you risk the saw jamming or snapping forward.

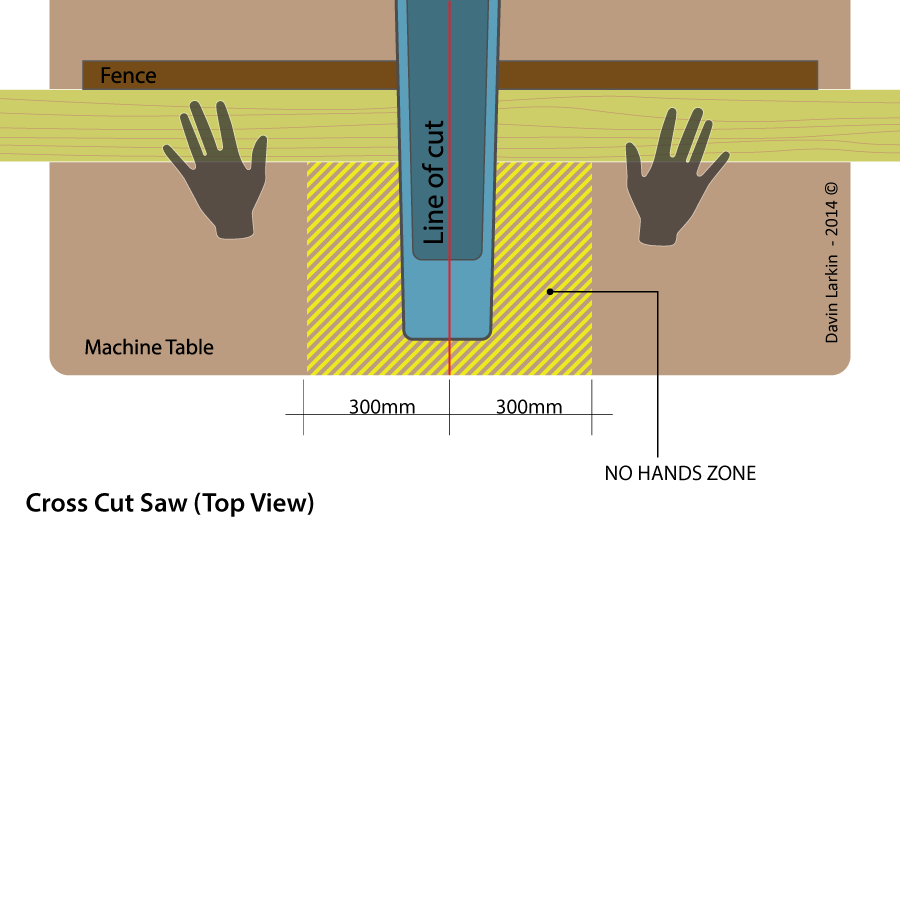

NEVER PUT YOUR HANDS IN THE LINE OF CUT FOR ANY REASON WHILE THE MACHINE IS RUNNING.

Always return the saw unit to the home position (behind the fence at the rear of the radial arm) before removing any material from the table.

After Use

Switch OFF the machine when finished or when leaving the machine temporarily.

If the machine is fitted with a manual brake this should always be operated before leaving the machine.

Regulations

Adjust guard to be no more than 5mm above the top surface of your material

Always obey the 300mm wide NO HANDS ZONE as shown in the image. This zone should be clearly marked on the machine table.

The Cross Cut Saw MUST be braked and stop within 10 seconds.

If an automatic break is not fitted some form of return device MUST be fitted. This return device will return the saw unit to its home position when the saw unit is released (e.g. spring-assisted return wire or counter balancing).